Do you have any questions?

Ask us by filling out the form below

By submiting my data I agree to be contacted

Continuously expanding our capabilities as a reliable industry partner

About us

Reliable industry partner

About us

The vast expertise and know-how in polyamide extrusion for perfect results

The ADLER-HIS was founded in 2015 as an industrial-scale manufacturing facility that offers advanced manufacturing services in the field of plastics engineering and provides support to industry partners to enhance their competency.

Our team members have vast experience in the practical implementations of high-performance polymers, as well as their extrusion and moulding technologies. These core competencies allow us to sustain a cost-effective manufacturing process that produces economically competitive and high-performance products for excellent thermal separation.

Our team members have vast experience in the practical implementations of high-performance polymers, as well as their extrusion and moulding technologies. These core competencies allow us to sustain a cost-effective manufacturing process that produces economically competitive and high-performance products for excellent thermal separation.

The vast expertise and know-how in polyamide extrusion for perfect results

The ADLER-HIS was founded in 2015 as an industrial-scale manufacturing facility that offers advanced...

manufacturing services in the field of plastics engineering and provides support to industry partners to enhance their competency.

Our team members have vast experience in the practical implementations of high-performance polymers, as well as their extrusion and moulding technologies. These core competencies allow us to sustain a cost-effective manufacturing process that produces economically competitive and high-performance products for excellent thermal separation.

Our team members have vast experience in the practical implementations of high-performance polymers, as well as their extrusion and moulding technologies. These core competencies allow us to sustain a cost-effective manufacturing process that produces economically competitive and high-performance products for excellent thermal separation.

Manufacturing

Our competencies are combined with fine-tuned extrusion and quality control tools for excellent results.

Quality assurance

Outstanding ADLER product quality on every unique bar

When creating our internal testing system for quality and functionality, we also considered the requirements of the EU DIN 14024 Standard.

Before the insulating profile goes into serial production, it withstands constant quality control assessments at all production stages: from quality assurance to packaging, and to the market lounge. All are evaluated based on the framework of our quality management system certified to ISO 9001 standard.

The reliable operations are the result of a well-established ERP & quality management system from material to final product.

Our specialised extrusion process is an efficient methodology of producing finished products of the highest quality in a wide range of sizes and different geometries.

We cover the entire product lifecycle from concept, design and quality assurance to manufacturing under the single roof. All in compliance with international standard guidelines.

Adler has a production facility of 2500 m2 with a fully automatic production lines. Production capacity is 40 mln. metres annually.

Manufacturing

Our competencies are combined with fine-tuned extrusion and quality control tools for excellent results.

Adler has a production facility of 2500 m2 with a fully automatic production lines.

Production capacity is 40 mln. metres annually.

We cover the entire product lifecycle from concept, design and quality assurance to manufacturing under the single roof. All in compliance with international standard guidelines.

Our specialised extrusion process is an efficient methodology of producing finished products of the highest quality in a wide range of sizes and different geometries.

We cover the entire product lifecycle from concept, design and quality assurance to manufacturing under the single roof. All in compliance with international standard guidelines.

Our specialised extrusion process is an efficient methodology of producing finished products of the highest quality in a wide range of sizes and different geometries.

Quality assurance

Outstanding ADLER product quality on every unique bar

The reliable operations are the result of a well-established ERP & quality management system from material to final product.

When creating our internal testing system for quality and functionality, we also considered the requirements of the EU DIN 14024 Standard.

Before the insulating profile goes into serial production, it withstands constant quality control assessments at all production stages: from quality assurance to packaging, and to the market lounge. All are evaluated based on the framework of our quality management system certified to ISO 9001 standard.

Raw Material

Strategic Supplier Partnership

We partner with only accredited suppliers to offer our products in more than 20 countries. Our suppliers are an integral part of our value chain, this is why our products are manufactured exclusively from tried, tested and superior engineered plastics in compliance with EN DIN 14024 Standard.

Strategic Supplier Partnership

RAW MATERIAL

We partner with only accredited suppliers to offer our products in more than 20 countries. Our suppliers are an integral part of our value chain, this is why our products are manufactured exclusively from tried, tested and superior engineered plastics in compliance with EN DIN 14024 Standard.

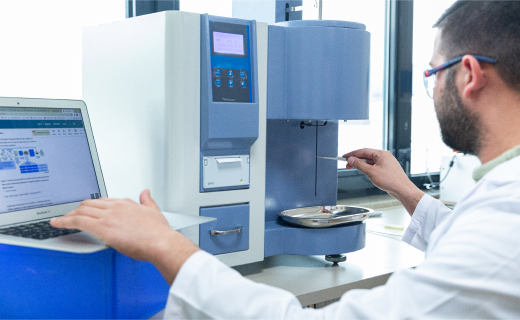

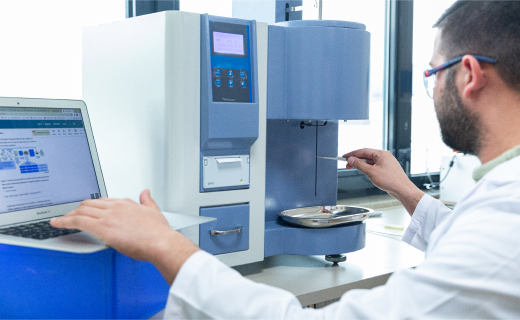

Quality control equipment

In our in-house laboratory, we conduct stringent tests from raw material quality to the full range of finished product properties:

All quality related measurements are checked and recorded before, during and after production, and all technical data is archived for tracking purposes.

- Melt Flow Index

- Tensile strength and elongation at break (Q)

- Density

- Fibreglass content

- Melting point and moisture absorption

- Permanent elasticity and shear strength (T, s)

All quality related measurements are checked and recorded before, during and after production, and all technical data is archived for tracking purposes.

Laboratory

Quality control equipment

In our in-house laboratory, we conduct stringent tests from raw material quality to the full range of finished product properties:

All quality related measurements are checked and recorded before, during and after production, and all technical data is archived for tracking purposes.

- Melt Flow Index

- Tensile strength and elongation at break (Q)

- Density

- Fibreglass content

- Melting point and moisture absorption

- Permanent elasticity and shear strength (T, s)

All quality related measurements are checked and recorded before, during and after production, and all technical data is archived for tracking purposes.

Laboratory

One access in QR code of each lot

Reliable logistic partners

Alongside profile extrusion, If necessary, we are able to assist you with the delivery of the product anywhere in the world.

Whether you require multi-modal transportation and collective consignment - our reliable logistic partners will develop an individual logistic concept tailored to your needs.

All parameters related to quality are frequently checked and recorded, and the corresponding data is archived for traceability during all types of production processes.

These measures ensure that all insulating profiles produced in our factory meet the most stringent quality requirements and perform the required functions.

Whether you require a standard or custom solution, all stringent testing processes provide you and us with the assurance of uncompromising performance and quality during all stages of production.

If required, we are happy to engage in individual contracts for additional tests or special product labelling in cooperation with our customers.

We offer several forms of packaging: wooden crates, metal baskets or return stacked-in stillages. Depending on your consumption volume and the frequency of deliveries, you will select the most convenient option.

We ensure that you receive your ordered insulating strips in compliance with the quality specifications and reliably on time.

Quality control

Logistics

One access in QR code of each lot

Quality control

All parameters related to quality are frequently checked and recorded...

and the corresponding data is archived for traceability during all types of production processes.

These measures ensure that all insulating profiles produced in our factory meet the most stringent quality requirements and perform the required functions.

If required, we are happy to engage in individual contracts for additional tests or special product labelling in cooperation with our customers.

Whether you require a standard or custom solution, all stringent testing processes provide you and us with the assurance of uncompromising performance and quality during all stages of production.

These measures ensure that all insulating profiles produced in our factory meet the most stringent quality requirements and perform the required functions.

If required, we are happy to engage in individual contracts for additional tests or special product labelling in cooperation with our customers.

Whether you require a standard or custom solution, all stringent testing processes provide you and us with the assurance of uncompromising performance and quality during all stages of production.

Logistics

Reliable logistic partners

Alongside profile extrusion, If necessary, we are able to assist you with the delivery of the product anywhere in the world.

We offer several forms of packaging: wooden crates, metal baskets or return stacked-in stillages. Depending on your consumption volume and the frequency of deliveries, you will select the most convenient option.

Whether you require multi-modal transportation and collective consignment - our reliable logistic partners will develop an individual logistic concept tailored to your needs.

We ensure that you receive your ordered insulating strips in compliance with the quality specifications and reliably on time.